For the last 1.5 years, we at the Impact Facility have been working with Fairphone, Signify and Huayou Cobalt to develop a programme that addresses the most urgent issues associated with the production of cobalt by artisanal miners in the Democratic Republic of Congo. As we are preparing for the public launch of our action platform, we felt the need to contribute to the discourse around artisanal mining of cobalt. Critically asking: What needs to happen to improve working conditions at artisanal mine sites and what is the downstream’s role in this?

Many hopes have been pinned on cobalt and its role in enabling a global transition to a green, technology-driven economy. Most electric vehicles (EVs) and smartphones use batteries with cathodes comprising nickel, manganese and, critically, cobalt. Given the relatively high cost of the mineral, battery manufacturers try to minimize cobalt content, but engineers struggle to remove it altogether. Cobalt is tightly linked to battery performance as it helps stabilise the battery during recharging. This means that as the production of EVs and the demand for large energy storage facilities increases, the market is looking for responsible sources of cobalt.

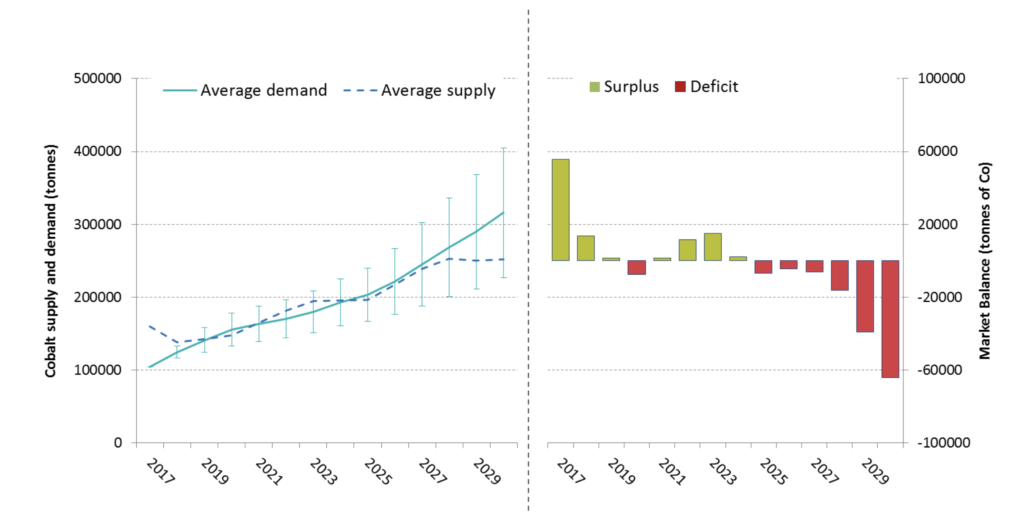

For a more sustainable and ethical supply chain, it could be argued that companies should seek to source recycled cobalt instead of newly mined material, following the basic rule to reduce, reuse, and recycle. Opting for recycled materials would appear to be an elegant solution to not only reduce the environmental footprint through a circular cobalt supply chain, but also to refrain from fuelling the challenges associated with the exploitation of newly mined cobalt. While we see an inherent value in recycling and laud the efforts that are put into further developing existing recycling technology, it is generally foreseen that cobalt demand will far exceed the amount of cobalt in rotation through recycling schemes. This means that cobalt mining will need to continue to satisfy a growing hunger for batteries to power electric vehicles, smartphones and other mobile devices in the foreseeable future.

Public discourse around cobalt, however, has predominantly been negative. Journalists and rights groups have drawn attention to the association of cobalt with serious human rights violations and appalling working conditions at the artisanal mines in Lualaba Province, Democratic Republic of the Congo, from where much of the raw material originates. This creates a dichotomy between cobalt as a key to reach a clean, carbon-free future on the one hand, and its production being characterised by systemic child labour, hazardous working conditions and a dismal reputation for the protection of human rights.

Throwing into sharp relief the unacceptable practices of some mine operations and the dire circumstances of mine workers, makes for compelling headlines, but can also lead to unintended consequences. Presented with the option to not source from places considered high risk, most manufacturing companies would willingly opt out. But by doing so, the very people whose lives are most affected – for whom the risk is the greatest – can be left bereft of a livelihood: the very thing that sustains their families and communities.

From where then, should companies source their cobalt?

The Democratic Republic of the Congo (DR Congo) is by far the world’s largest cobalt producer. The southern province of Lualaba (formerly Katanga), also known as the Copper Belt, has a long history of industrial mining, where rich cobalt deposits are found alongside copper.

These resources are concentrated in and around just a handful of cities, and are said to be some of the largest in the world estimated to comprise 51% of global cobalt reserves and currently more than 70% of global production – an equivalent of 100,000 metric tons in 2019 (USGS, 2020).

While large-scale cobalt mining operations account for approximately 80-85% of freshly mined cobalt production, artisanal mined (ASM) production has historically provided flexibility to the battery industry at times when large mines were not operating. At its height, after the end of the second Congo war (2002), an estimated 90% of all cobalt mining was artisanal. Today, ASM is said to make up about 20% of Congolese national production, totalling approximately 20,000 tonnes in 2019.

About four years ago, Amnesty International was the first international campaign to draw attention to the systemic occurrence of child labour associated and hazardous working conditions at artisanal cobalt mines in the mining city of Kolwezi. The report picked out a particular mine, locally known by the name of the neighbourhood: Kasulu. Formerly a residential area, Kasulu has since been designated a “Zone for Artisanal Exploitation” (ZEA) – an area dedicated to the recovery of cobalt ore and other minerals by small groups and individuals using basic techniques and rudimentary tools. Amnesty and other rights groups estimated the total number of children working across such mines to be as high as 35,000, while more conservative estimates believe the real number is closer to 5,000 children. Clearly, 5,000 children at work is significantly less than 35,000, but is still a very alarming figure given the effects of child labour on the individual and their families. As well as child labour, newspapers and NGO reports highlight the number of accidents and tragic deaths often as a consequence of having dangerously deep excavation pits. The precariousness of these deep pits is further destabilized by the practice of digging tunnels horizontally, creating ‘galleries’.

As unyielding as the very serious problems found at artisanal cobalt sites appears, and as precipitous the climb to address them surely is, the goal to bring some relief to mine workers through improving site conditions is not impossible. Professionalizing ASM is a strategy that has been pursued with success in ASM gold operations in South America. Some Colombian and Peruvian gold mines, for example, have been unrecognizably transformed over the course of the last 20 years from disparate groups of diggers scraping a living on the edge of the economy, to organised, legal, small enterprises providing for their families and integrated into rural communities. Driven by the introduction of national legislation, but also due to the leadership and support of mission-led organisations such as the Alliance for Responsible Mining, Fairtrade, Solidaridad and the Swiss Better Gold Association, the sector has leaped far and achieved much through the formalization and professionalization of artisanal mines. These efforts required considerable investment, but ultimately resulted in certified, responsibly produced gold demanded by jewellers and electronics OEM in Europe and the USA creating positive supply chain relationships some of which have endured over a decade or more.

Driving the production of responsible ASM cobalt will take a similar effort, but one that can be sped up by building on what has been learned from other commodity sectors, such as tin and gold, and made more efficient if every cobalt supply chain actor takes responsibility to contribute to the solution. Supporting ASM to professionalize will have huge implications. With more than 100,000 men and women linked to the ASM cobalt sector in the Kolwezi region, concentrated efforts to raise production practices will result in improved livelihoods for entire communities. Nor are we starting from an uncharted base. We can learn from gold and tin, but improvement projects are also underway in cobalt.

Developing responsible ASM cobalt supply – taking inventory

Witness the work of NGOs, buyers and mining concession holders at the Mutoshi ASM project in Kolwezi. From a site that was notorious for uncontrolled digging to 70 metres by over 10, 000 miners with picks and shovels rented from Chinese traders in exchange for discounted minerals, the area is now highly formalised with organised groups of artisanal working restricted to tunnelling to less than 20 meters.

Workers go about their day in a relatively safe and clean industrial setting and sell the ore they’ve recovered at a selling station with transparent pricing and monitored grading analysis and weighing scales. Children are not permitted at the site, and its boundary is policed and entry controlled by barriers with digital identity card readers. Although not all the elements are transferable to other ASM sites, Mutoshi is a ‘model’ mine in many ways, providing workers with a productive and safe means of making a living.

Another inspiring example is the previously mentioned Kasulu mine site, originally standing at the core of Amnesty International’s report “This is What We Die For” due to the presence of thousands of children participating in the then uncontrolled mining activities. Since then, the Kasulu mine site has undergone a significant formalization effort. Now walled off to prevent uncontrolled ingress, with designated market depots, a hospital and offices to house the cooperative managing the site, Kasulu is being independently monitored and officially child-labour free. All this, to a large extent, due to the very significant commitment of the Chinese-owned crude refiner Congo Dongfang International Mining SARL (CDM), the Congolese subsidiary of Huayou Cobalt. In the past four years, Huayou Cobalt, the very company that was the bullseye of human rights activists’ target, has invested millions of dollars to finance the formalization of Kasulu, without formally owning or controlling the site.

Working conditions at the mine sites are still far from adequate and there have been reports of serious injuries and, thankfully infrequently, fatalities that attest to the daily hazards faced by diggers. Also, establishing the site required the relocation of households by the provincial government, a process that has been criticized by several parties;. But in a sector where most artisanal mines operate illegally and where child labour is still widespread, Kasulu poses a significant achievement that should create hope that any mine site can be made safer for its workers, even though progress might be gradual, accepting that setback will occur along the way, and recognizing that real change requires substantial investment.

In a recent publication of the Financial Times, however, news broke that Huayou Cobalt temporarily ceased its buying relations with all artisanal mine sites in the DR Congo. A decision that must have been difficult to make after having invested so much money and effort to get the Kasulu site to where it is today. Nearly four years after the public was made aware of systemic child labour in the cobalt sector there is still no best practice standard for artisanal operations that enjoys industry-wide acceptance, although discussions among key stakeholders are currently underway. In the absence of an assured ‘responsible artisanal supply”, many downstream and midstream buyers restrict their procurement strategy to non-ASM material – driven by the desire to avoid association with the potentially negative impacts on workers and local communities.

For Huayou Cobalt, careful piloting is needed to navigate the perilous waters between international market perceptions and commercial contracts and the need to help artisanal miners and their families locally. It has become an imperative to have agreed a common standard and for their work to improve conditions at mines recognized by buyers in the supply chain. Mark Dummett, head of business, security and human rights at Amnesty, cited in the aforementioned Financial Times article, rightly warns of the unintended consequences that disengagement from ASM can have. Dummett points out the fact that ASM provides ”a lifeline for millions of impoverished people in the DRC. As has been witnessed in the tin industry in the DRC, a too-rapid reaction by downstream markets can lead to harmful effects on the very people and communities that are the subject of concern. Downstream disengagement from or a ban of ASM sites do not constructively address the issues leading to child labour and hazardous working conditions in the first place. Instead, it can result in the abdication of any responsibility by supply chain actors to contribute to jointly developing a viable solution and further deepening the poor reputation of the sector.

Recognizing the importance of the ASM sectors regionally, companies along the supply chain have a responsibility to be a part of finding solutions to the complex challenges at hand. Unilateral disengagement, or even a collective ban, is unlikely to ever incentivise change to improve the working conditions and operational practices at ASM sites.

In their response to the Financial Times article Huayou Cobalt clarified that even as they temporarily pause commercial relations, their commitment to ASM formalization remains strong, as they will continue to contribute the development of a industry-wide ASM standard to define responsible production as well as offer their continued support to the mine sites of Kasulu and Kamilombe jointly investing more than USD 4 million in concrete, timebound improvements at the mine sites as part of their collaboration with Fairphone, Signify and The Impact Facility.

The way forward

Both the Mutoshi project and the commitment of the Impact Facility and its partners to improve conditions at two mine sites are great first steps, and set a great example for what is possible. But they are not enough. There are more than 50 designated mining areas for artisanal mining (ZEA), many of which are dormant, as well as dozens of sites in the region that operate illegally or in legal grey zones, missing at least some of the licenses needed to run a mine. Knowing that ASMhas contributed 20, 000 tonnes of cobalt in 2019 alone, our focus cannot be on creating small islands of responsible supply, in a sea of trouble. It is time to think big and collaborate to transform the region, since the issues we are all concerned about, such as child labour and poverty, can be easily displaced to other sites, and putting up walls creating small bubbles of good practice that can be easily burst. As global cobalt demand is forecasted to skyrocket in the coming years, this approach won’t fly. Our ambition should be to lift all boats, by engaging miners, meeting them where they are and jointly taking pragmatic steps towards reaching our expectation that mine workers have a safe and stable, well paying job, while their children enjoy their right to education and a childhood.

Such efforts need considerable investment into mining communities upstream, but pale in comparison to the cost of inaction if downstream businesses continue to stand back. Either strategy — disengagement or waiting for the mines to spontaneously meet yet-to-be-defined international standards — will not help to solve the poor reputation of cobalt mining in the DRC, because the dire conditions of mine workers will persist.

Rather than investing effort and resources on ensuring disassociation from ASM, companies should be channelling energy into programmes that seek constructive engagement on the ground, actively contributing to creating the conditions that all would like to see at ASM mine sites. Given the scale of the issue, it is easy to feel overwhelmed, but by leveraging the power of an entire industry the whole mining region might be transformed for the better.

We should embrace a collective responsibility for action. Any organisation operating as part of — or associated with — the global cobalt supply chain should consider how it might best contribute to a solution. This responsibility encompasses large-scale mining organisations, refineries, battery manufacturers, electronics manufacturers and auto OEMs. The public sector also has a role to play, as do international development agencies and private foundations and NGOs, industry associations, and metal marketplaces. All are needed to establish an industry-wide acceptance of cobalt from responsible ASM.

Monitoring is not an end in itself. It must inform action and drive needs-based improvements on the ground. In our work we do not talk less about corrective actions, implying that mines should already operate at a higher management level, and more about continuous improvement. Meeting mines where they are, jointly taking measures and mobilizing the funds needed to transform these mine sites. Each of them on their individual improvement trajectory. Unless we adopt radical inclusivity, we will struggle to truly change the way artisanal mines are operated in the region.

We should ask ourselves: Are we focusing on the right metrics? By solely quantifying the number of children negatively affected by mining, the number of illegal mine sites and human rights violations we remove ourselves from being part of a constructive solution. We can commission as many studies as we want, most likely the situation on the ground will not magically improve. Instead, we should deploy interventions that aim to quantify real impact on the ground, tracking how many children have been put back into school, reductions of health and safety incidents, increases of miner income and the number of people that participate in savings groups, putting aside money to invest in a better future.

What now?

As an action platform, the Fair Cobalt Alliance invites all organisations to join the founding partners already investing in mine improvements, the eradication of child labour and the economic diversification in mining communities. The Fair Cobalt Alliance provides the vehicle through which to pool funds from multiple organisations able to donate at very different levels, and a management umbrella for our programme comprising several targeted interventions.

Equally important is sending a strong market signal recognising the legitimacy of cobalt from responsible ASM operations. Through public policies and internal responsible sourcing strategies, companies have powerful tools to acknowledge the potential for ASM operations to be a legitimate economic activity contributing to local development and an important livelihood for thousands of community members in Lualaba, DR Congo. Pledging to the Fair Cobalt ‘Call to Action’ is a concrete path to promote the continuous improvement of working conditions and environmental management at ASMoperations.

For more information, contact [email protected].