Introducing Cobalt Credits: Responsible sourcing starts with taking responsibility

Guest Authors

View ProfileOther posts by

Guest Authors:

This is a guest blog authored by Angela Jorns, the Fair Materials & Mining Lead at Fairphone, and David Sturmes, Fundraising & Business Development Director at The Impact Facility. Fairphone is a Dutch social enterprise that, by making a smartphone and other electronics, is building a movement for fairer electronics, seeking to open up the supply chain, and creating new

This is a guest blog authored by Angela Jorns, the Fair Materials & Mining Lead at Fairphone, and David Sturmes, Fundraising & Business Development Director at The Impact Facility. Fairphone is a Dutch social enterprise that, by making a smartphone and other electronics, is building a movement for fairer electronics, seeking to open up the supply chain, and creating new

relationships between people and their products.

How Fairphone and The Impact Facility developed a new system to enable investment into improving working conditions of artisanal cobalt miners in DR Congo

As part of our engagement in the Fair Cobalt Alliance (FCA), Fairphone and The Impact Facility (TIF) worked on finding a solution for downstream companies to proactively source ASM cobalt from mine sites committed to adopting safer, child labour-free production practices.

Fairphone’s objective was always to integrate material from FCA partner sites into our supply chain. But this has proven extremely difficult for a host of reasons.

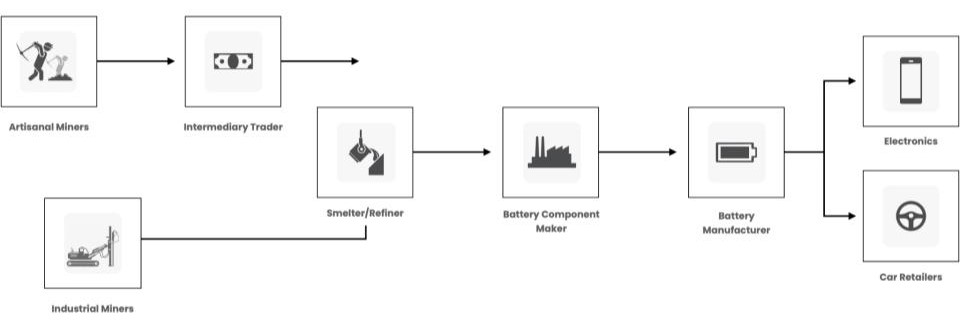

The ASM cobalt sector is highly informal. Currently there are no official market channels in the DR Congo that would allow for ASM cobalt to formally enter into the global battery supply chain. Additionally, the battery supply chain is fairly complex, comprising several different tiers.

The business relationships between these supply chain tiers are based on a multitude of factors, taking into consideration the technical specifications, pricing, and quality; with little possibility for influence by downstream companies like Fairphone. In addition, these tiers frequently change mid- and upstream, and cobalt from different sources gets mixed into the chain at various tiers. All of that means that officially and physically integrating traceable ASM cobalt proves to be difficult.

Why do we use cobalt in our devices?

Cobalt is a critical material for lithium-cobalt-ion batteries predominantly used in our smartphones and other mobile electric devices, electric cars, and for intermittent energy storage solutions.

Introducing: Cobalt Credits – a pragmatic, impact-driven approach to the responsible sourcing of ASM Cobalt

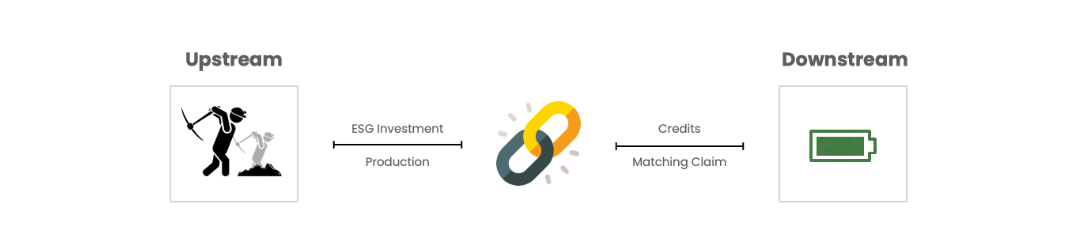

That’s why we worked with the FCA’s Supply Chain Integration (SCI) task force to develop an alternative route that allows for a pragmatic and scalable solution designed to drive positive impact on the ground. This is how we landed on the idea of developing cobalt credits to serve as a mechanism through which downstream companies can address the salient issues related to ASM cobalt that flows into the global battery supply chains – by acquiring credits commensurate with their usage of cobalt.

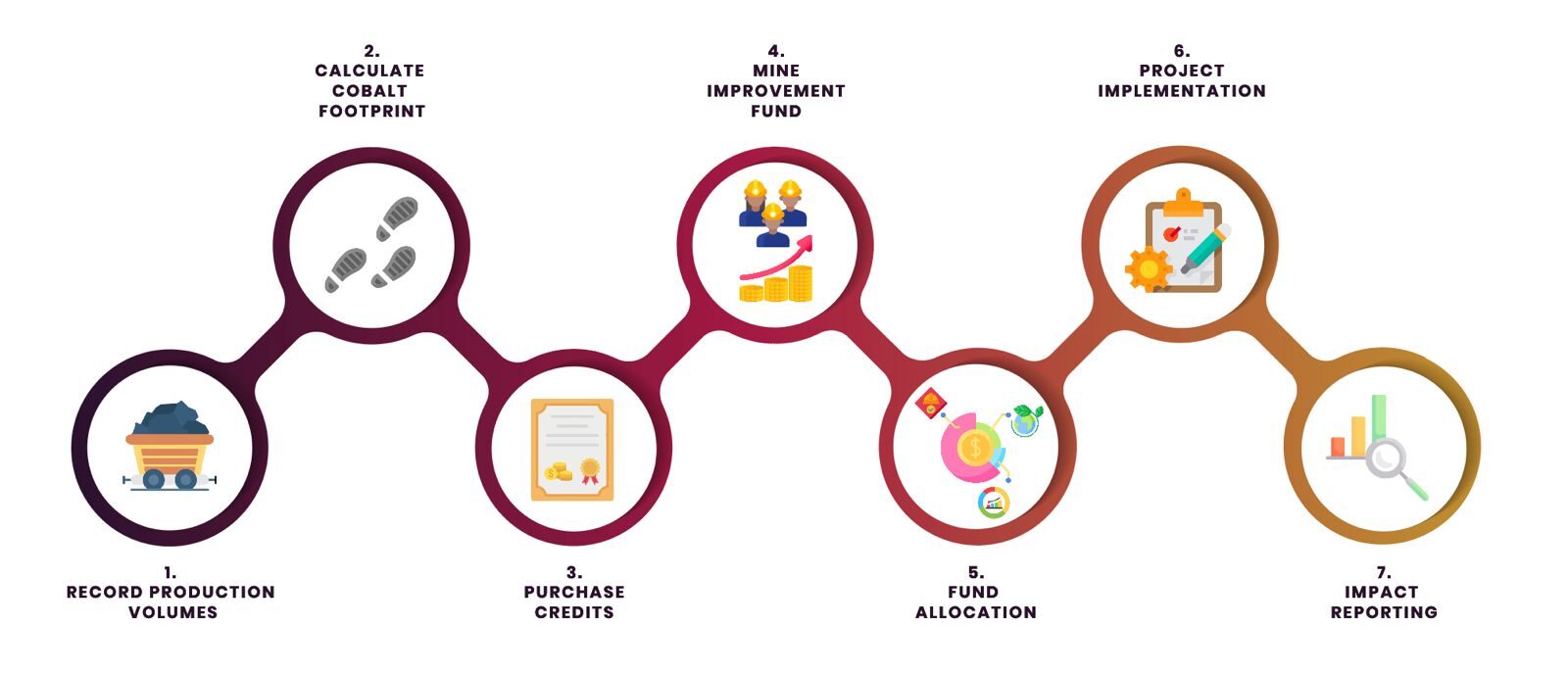

So how does that look in practice? For the last three years, the FCA has worked with a local partner cooperative, CMDS, who operate the Kamilombe mine site where more than 6000 artisanal miners are producing cobalt. CMDS tracks its cobalt production, verified by the staff of The Impact Facility. For every metric tonne of cobalt produced, one cobalt credit is generated that can be purchased by downstream cobalt users such as Fairphone. The revenue generated through the cobalt credit sales is then channeled into a Mine Improvement Fund, managed by the FCA, to finance projects that improve the conditions of artisanal miners. Together with CMDS, we have formed a Fund Allocation Committee (FAC) comprising mine site workers (diggers, haulers, transporters, and washerwomen) to set improvement priorities based on their needs. Aligned with international standards for responsible ASM production, the FAC can develop and prioritise interventions that address and improve the mine’s health and safety conditions, environmental management, mitigation of child labour, or better and more transparent business practices.

Visit our website to learn more about how the Cobalt Credit system has been developed and is governed.

Piloting Cobalt Credits with the launch of the Fairphone 5

For Fairphone to pilot the cobalt credits, we required an understanding of our cobalt “footprint” i.e., the total amount of cobalt we used in our products in 2023. Only in this way, Fairphone could state that it accounts for its full cobalt use in 2023 through credit purchases and that all the cobalt used in Fairphone 5 (and our other products) helps improve the working conditions for artisanal miners.

Fairphone obtains a Full Material Declaration (FMD) from its suppliers for each product as a standard practice. This document shows us what kinds of materials and how much of them are used in our products, including cobalt. We then multiplied the amount of cobalt in each product by how many of these devices we would sell to customers in 2023 – initially as a projection, with the intention of taking final stock at the end of the financial year.

This is how we came to a full (projected) cobalt footprint of a bit less than 2.5 tonnes in 2023. We then multiplied this with the cobalt credit price of 5000 USD per tonne – which had been agreed with the miners cooperative and the FCA SCI task force, based on a 10% average of the cost of cobalt over the past few years.

This means that Fairphone is paying approximately 12,500 USD into the cobalt credit fund for the pilot, commensurate to our cobalt consumption in 2023. This will be invested by the miners into the improvement of the mine site. With this, we can say that 100% of the cobalt used by Fairphone in 2023 supports improved conditions for ASM miners. This represents something between 5 and 10 USD cents per device that we sell (depending on whether it is a Fairphone 4, Fairphone 5, or Headphone). An amount that we find entirely feasible and justified and also replicable for other companies. At the same time, if the cooperative were able to sell credits for just half of its production, this could generate in excess of USD 1 million a year for mine improvements.

How cobalt credits bolster Fairphone’s approach to responsible sourcing

Of course, all this does not reduce our obligation to conduct in depth due diligence into our physical cobalt supply chain. In fact, both go together – we know from our due diligence that the cobalt we use comes from the DRC and that it is highly likely that at least part of it is sourced from ASM. The purchase of cobalt credits, and generally our engagement in the FCA, is a way for us to address these salient issues in our supply chains and invest concretely in prevention, mitigation, and positive improvement in the sector – in line with our footprint and responsibility.

We believe that cobalt credits, and generally credit systems (or “book and claim” systems) have a particular merit for downstream companies in specific situations:

- 1) When a material is spread across many sub-components of the product and only occurs in tiny amounts or in alloys,

- 2) When (therefore) supply chains are extremely widespread, long and complex, or

- 3) When a formalised, reliable chain of custody into the product is not yet possible – which is the case with cobalt from ASM in DRC. Ultimately, Fairphone still aims to physically integrate cobalt from the FCA partner sites into its product, but achieving this is only possible in the longer term.

So what’s next?

The pilot of the cobalt credits is by no means complete or perfect, and we intend to further develop and improve the model based on the lessons learned. But with the pilot, Fairphone, TIF and the FCA have been able to prove the concept of cobalt credits. The mechanism is open for other companies to join, and we invite industry players to collaborate with us to further develop it. Ultimately, we want to encourage the industry to use this innovative way of addressing salient issues and improving conditions in cobalt ASM mining, in line with their cobalt use.