Establishing fair trading practices at artisanal cobalt mine sites

One of the Fair Cobalt Alliance’s three strategic objectives is increasing the incomes of artisanal miners and their wider community. Key to that strategy is ensuring fair value retention at the point of mineral sales.

While artisanal miners are, on average, earning more than many other community members, most mine workers complain about the lack of transparency of current trading practices, often accusing traders of taking advantage of their inability to accurately determine mineral content and value.

Committed to developing replicable and scalable interventions, the FCA has developed this document to guide the development and adoption of fair trading practices across artisanal mine sites. We consider a fair price a price that results from accurate purity and weight determination and with a logical link to international cobalt (and copper) prices.

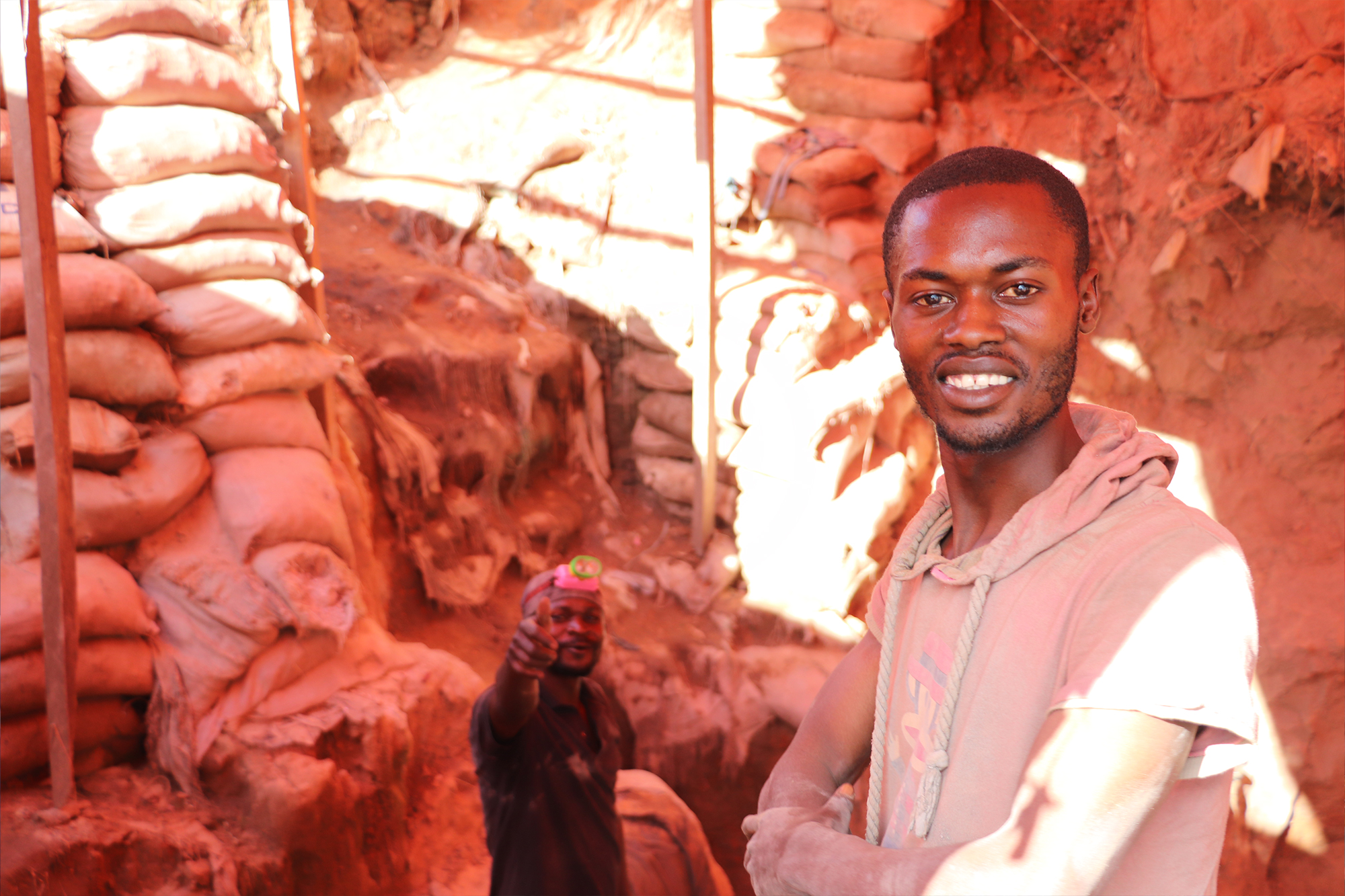

Artisanal miners labour for long hours, placing themselves in harm’s way to extract cobalt from shafts whose structural integrity is not guaranteed. In a predominantly cash-based economy, artisanal miners often feel shortchanged on the weight and purity of their ore by the traders buying the material from them.

Additional background

Based on the FCA’s engagement with artisanal miners on the Kamilombe mine site and across the region, we know that miners have little or no trust in the accuracy of purity and weight measurements conducted by traders.

In addition to miscalculating mineral content, many mine workers report that they have to choose between being compensated for either copper or cobalt. Meanwhile, there is no reason to assume that traders are only paid for one of the two minerals as they sell it on to the next party in the supply chain.

Defining fair trading practices

To ensure fair trading practices, we will need to ensure:

- Proper Sampling: To ensure fair compensation, the sample used to measure metal content needs to be representative of the metal batch being sold. It is easy to manipulate the quality of a sample by focusing on lower-grade material, which can be done simply by eyesight, as both copper and cobalt are visible to the naked eye. To ensure that the sample is representative, traders would need to adhere to a transparent and replicable sampling methodology.

- Accurate purity measurement: It is common practice to use XRF machines to determine the purity of a sample. These machines require accurate calibration to produce a reliable reading. It requires several readings to derive a representative average across a sample.

- Pricing transparency: Local buying prices should be linked to the international market prices for copper and cobalt so that miners have a clear indication of what they can expect from their mineral sales. A pricing formula will need to factor in the grade of the material, as low-grade material is purchased at a discount, due to the cost of transport for large volumes of ore.

Artisanal miners often transport and sell their material to traders, locally referred to as Négociants, at depots buying large amounts of cobalt before selling them on to crude refineries. Some depots exist on-site and other a distance away from the mine location. In this case, miners often choose to pay for the transport of the material.

Translating theory into practice

In an effort to increase transparency and fairness as per the above, the FCA proposes the following activities to be implemented in collaboration with cooperatives and traders.

- Professional sampling:

Short-term: Develop an official sampling methodology

At the moment, minerals are sampled manually, first hand selecting stones, then crushing them manually and burning off excess humidity over hot coals. To achieve representative sampling, the FCA seeks to co-develop and publish a guide for proper sampling for the selection of ore and subsequent processing steps.

Long-term: Create a sampling facility

Alternatively, or as a next step, investment into a mechanical sampling station at the mine site could also be considered. Such an installation would likely include jaw crushers for a reduction of ore size, followed by a tumbler to achieve a homogenous sample, before pulverising and drying the sample. This equipment can facilitate achieving a homogeneous mix of materials to increase the efficiency of the sampling methodology, while decreasing the risk of OHS incidents, as current sampling exposes people to various hazards. As a next step, a more detailed installation design and budget should be developed.It is important to note that although this process would result in a more professional assessment of the purity, the unintended consequence of replacing this infrastructure would de facto displace workers responsible for manual crushing at the mine sites. - Purity assessments

Short-term: Introducing control units

The FCA is planning to provide control units – so-called blanks – to the miners. A blank is a small piece of metal with a known copper and cobalt concentration that can be used to assess the accuracy of the XRF calibration.In practice, miners would check the XRF meter, by having this piece of metal checked by the trader, knowing what the results should be. If the reader or the meter shows any deviation from the known concentration, miners should request a calibration of the XRF prior to transacting.Long-term: Offer independent assessments

In parallel to constructing a sample-taking facility, the introduction of facilitating independent purity assessments could be considered. The operation of such a service should be led by parties not involved in the trade and with no commercial stake in the transactions. As such, such a service could be offered by or in collaboration with relevant 3rd actor(s). - Improved pricing

Short-term: Publish international pricing

The FCA should request partnering cooperatives to proactively publish an international reference price and a formula for determining mineral value. Pricing data can easily be shared during weekly worker meetings currently held on Monday mornings for health and safety instructions and general updates.

At the depots, XRF machines are used to assess the purity of the cobalt, after checking for its weight. To be accurate, these machines need to be carefully calibrated; there is currently no structured system to easily verify accurate calibration and traders have been continuously accused of intransparency in their measurements.